Inter-Esterification Plant

We at N&T Engitech offer facilities for Inter-Esterification units and the fabrication of all equipment related to the same.

We use a modern Inter-Esterification technics that helps to modify the overall oil's physical properties through the interchange of fatty acids inside and between several triglycerides using catalysts. This is facilitated by a catalyst working under a vacuum and operating at operating temperature.

The plants, we offer at N&T Engitech are fully automated and are developed using high-quality materials to ensure that they perform flawlessly. Also, these machines are easy to use and durable.

The process we follow to Create Inter-esterified Oil

At N&T Engitech, we follow specific steps while creating an inter-esterified oil, as illustrated below.

Homogenization and Heating

From the storage tanks, soft and hard oils are directed to the homogenizer, where they are heated to mix appropriately.

Catalyst Addition

At this stage, catalysts such as sodium methoxide are added to trigger a random rearrangement of fatty acids, thus adjusting the physical characteristics of fat, such as plasticity or melting point.

Interchange of Methyl group

The added catalyst is stirred vigorously to propagate the reaction, leading to the interchange of the Methyl group.

Heating

At this stage, oil is heated.

Drying and Acid addition

In this process, the Inter-esterified oil is transferred to a cooler, and necessary acids are added to reduce the soap generated during the process.

Bleaching

This process is carried out to remove colour pigments in oils, thus enhancing the appearance of the oil.

Polishing

This step removes the micro particle to give brilliancy to the product.

Benefits of Inter-Esterification Plant

Here at N&T Engitech are known for the provision of high end Inter-Esterification plant to cater for all your production equipments to ensure that your oil goes through the proper process.

How We Work

N and T Engitech operates by providing innovative engineering solutions and services, leveraging expertise to address complex industrial challenges effectively.

Planning & Design

Initial phase involves project conception, site selection, & architectural & engineering design.

Construction & Execution

Once the planning and design phase is complete, actual construction begins.

Finishing & Commissioning

All systems & equipment are thoroughly tested & commissioned to ensure they operate as intended.

Experience the best in Inter-Esterification Plant manufacturing with N&T Engitech.

Discuss your requirements and transform your oil production process with our advanced technology and expertise.

Other Technology

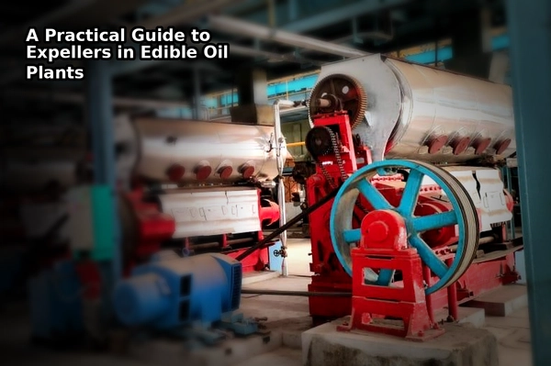

Utilizing cutting-edge technologies, N&T provides engineering, procurement, and construction solutions for all equipment related to seed crushing procedures.

Why Choose Us ?

There are several reasons why you should choose to do business with N&T Engitech. Here we give:

Affordable machines

At N&T, we offer machines at pocket-friendly prices which suit all types of customers.

Automated machines

The machines we offer are developed using the latest technology, which enables the automation of most operations, thus limiting human operations.

After-sale assistance

Here at N&T Engitech, we have a team of highly qualified professionals who are readily available to offer after-sale assistance to our clients.

High-quality machines

At N&T Engitech, we offer machines that are developed using high-quality materials for flawless performance.

Our Respected Clients

We are honored to collaborate with the most top organizations in the Engineering Procurement and Construction industry.

Projects

Our Accomplished Projects

N&T steadily offers cutting-edge expertise to big and small enterprises for a diverse range of uses and environments all over the world. Browse through our completed project list.

Our Certification & Awards

N&T employs the most cutting-edge, creative professionals who are actively learning about evolving EPC standards.

Experience

Clients

Best Team

Our Blog

Browse most recent blog & news from N&T. View Engineering Procurement Construction related news, and articles.