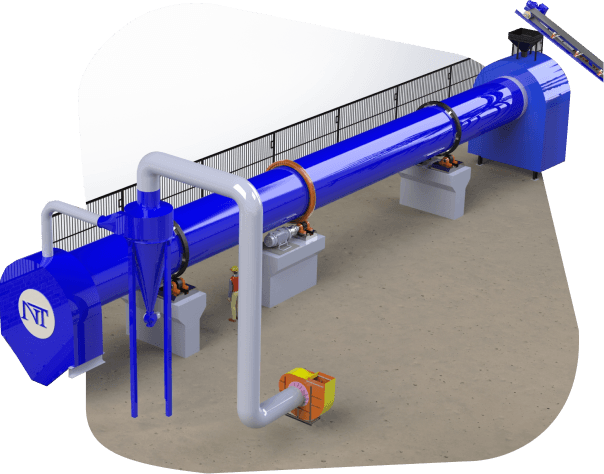

Industrial Rotary Dryer manufacturers

We are expert manufacturers and exporters of high-quality Rotary Dryer, meticulously crafted using premium components and the latest technology in process engineering.

As leading rotary dryer manufacturers and exporters, we offer top-tier industrial drying equipment designed to effectively remove moisture from various materials. Our rotary dryers are essential in industries such as cement, mining, building materials, chemicals, food, metallurgy, and fertilizer production.

They excel in processing materials like slag and clay. The primary function of our rotary dryers is to reduce the moisture content of materials to the desired level, facilitating further processing or storage. With our advanced technology and quality craftsmanship, our rotary dryers are an indispensable asset for efficient and reliable drying operations.

Technical Specifications of Cement Rotary Kilns

We Offer a Diverse Range of Rotary Dryer Models Tailored to Fit Your Business Needs

| Material | : MS-IS2062 /Equivalent |

|---|---|

| Production Capacity | : 3 TPH to 50 TPH |

| Power Consumption | : 10 KW to 220 KW |

| Fuel Type | : Wood Fire/Coal fire /Pallet fire |

| Automatic Grade | : Manual/Semi automatic |

| Drive | : 50 HZ/60 HZ |

| Inclination | : 3 to 6.5 Degree |

| Country of Origin | : India |

How Our Rotary Dryer Works

Our rotary dryer efficiently processes materials by leveraging advanced drying technology for optimal moisture removal.

Raw Material Handling

We expertly manage raw materials, ensuring they are correctly prepared and conveyed for the drying process.

Crushing

Our system includes a robust crushing mechanism, essential for breaking down materials into suitable sizes for effective drying.

Hot Air Generator

Utilizing a state-of-the-art hot air generator, our rotary dryer heats materials uniformly, ensuring efficient moisture evaporation.

Drying

The core of our system, where materials are evenly dried to the precise moisture content required for your specific application.

Discharge and Storage

Post-drying, materials are smoothly discharged and prepared for secure storage or immediate use.

Diverse Applications of Rotary Kilns in Various Industries

Experience Cutting-Edge Technology with N and T Engitech's Rotary Kilns: Your Ideal Solution for Industry-Specific Thermal Processing Needs.

Food and Dairy Industries

Chemical Industries

Metal Industries

Agriculture Industries

Sand Industries

Wood and Paper Industries

How We Work

N and T Engitech operates by providing innovative engineering solutions and services, leveraging expertise to address complex industrial challenges effectively.

Planning & Design

Initial phase involves project conception, site selection, & architectural & engineering design.

Construction & Execution

Once the planning and design phase is complete, actual construction begins.

Finishing & Commissioning

All systems & equipment are thoroughly tested & commissioned to ensure they operate as intended.

Enhance your mineral processing with our Industrial Rotary Dryers

Partner with us for a drying solution that is as unique as your business needs.

Other Technology

As a leading supplier and manufacturer, aiming to bring versatile cement technologies and plants. Our focus is on enhancing your industry's optimum productivity level with innovative solutions.

Why Choose Us for Your Rotary Dryer Needs?

Our unique approach and advanced technology distinguish us from other rotary dryer manufacturers, ensuring superior performance and efficiency in our products.

Good Drying Quality

Our products are thoroughly checked for top-notch quality, meeting international standards for lasting performance and efficiency.

Custom Solutions

We specialize in creating customized dryer solutions, perfectly aligning with your project's unique needs.

Long Service Life

Our products are designed for durability, ensuring a prolonged lifespan and reliable performance over time.

Large Capacity

Engineered to handle substantial volumes, our dryers offer ample capacity to meet your large-scale processing needs.

Expert Support

Our skilled team is always available to offer technical help and advice during every stage of your project.

Global Reach

Our widespread network ensures we can supply our products and services worldwide, directly to your location.

Our Respected Clients

We are honored to collaborate with the most top organizations in the Engineering Procurement and Construction industry.

Projects

Our Accomplished Projects

N&T steadily offers cutting-edge expertise to big and small enterprises for a diverse range of uses and environments all over the world. Browse through our completed project list.

Our Certification & Awards

N&T employs the most cutting-edge, creative professionals who are actively learning about evolving EPC standards.

Experience

Clients

Best Team

Our Blog

Browse most recent blog & news from N&T. View Engineering Procurement Construction related news, and articles.

Frequently Asked Questions

In the cement industry, a rotary dryer is primarily used for drying raw materials before they are processed into cement. This includes reducing moisture content in limestone, clay, and other raw materials to improve the efficiency and quality of the cement production process. By pre-drying these materials, rotary dryers help ensure a more consistent and quality product, while also enhancing the overall efficiency of the cement manufacturing process.

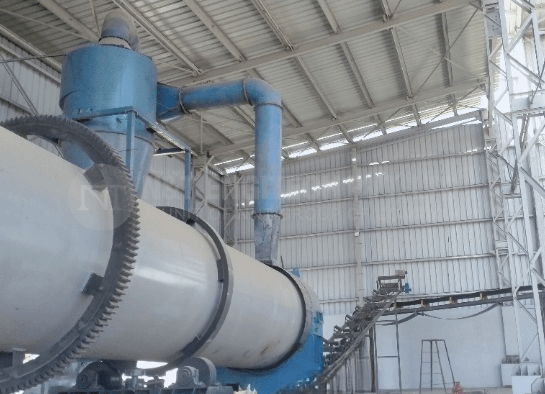

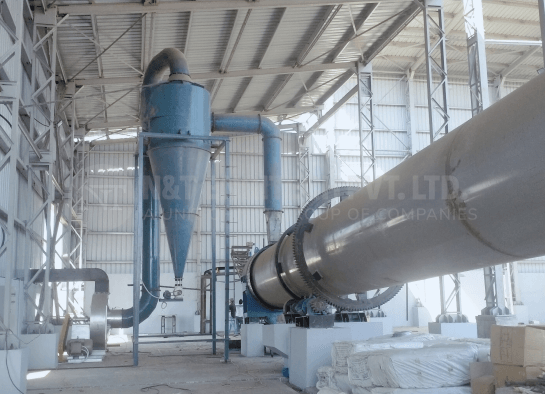

In the cement industry, the working principle of a rotary dryer involves the use of a rotating cylinder to facilitate the efficient drying of materials like limestone and clay. As the cylinder rotates, the material is lifted and showered through the hot gas stream, effectively reducing moisture content and preparing the material for subsequent processing in cement production. This rotation, combined with the heat and airflow, allows for uniform and efficient drying.

The shell of a rotary dryer is typically made from metal, often a steel alloy or stainless steel. This choice of material ensures durability, resistance to high temperatures, and the ability to withstand the continuous stress of rotating and holding the material being dried.

Rotary dryers are most commonly used in industries where bulk materials need to be dried efficiently and consistently. This includes sectors such as:

1. Cement Industry

2. Food Processing

3. Chemical

4. Agriculture and many More.