Seed Crushing Plant

Precision oilseed crushing machines for top-quality oil production. Milling experts delivering excellence.

Discover excellence in high-quality oilseed crushers and seed oil crushing plant solutions. Our cutting-edge oil seed crushing machine and oilseed crushing equipment, combined with expertly designed seed processing machinery, guarantee top-tier performance.

We specialize in delivering precision, efficiency, and quality in every aspect of seed processing. From advanced oilseed crushing machines to comprehensive seed processing solutions, our commitment to innovation and customer satisfaction drives us forward.

Trust us for industry-leading expertise in oilseed crushing and seed processing machinery, ensuring optimal oil extraction and processing results. Elevate your operations with our state-of-the-art seed processing solutions today.

The Process of operation

N&T supply the plants to process all types of oil-bearing seeds like Sunflower, Mustard (High Pungent & Expeller Oil), Sesame, Cotton seeds, Groundnuts etc must be effectively-prepared to attain maximum yield and high-quality product. At N&T Engitech, the key steps used while creating seed oil include:

Cleaning

N&T Engitech cleaning machinery is a vibrating unit used to separate impurities and trash from seeds/nuts. This process is vital because, apart from lowering oil processing machinery wear and tear, oilseed cleaning help to improve oil yield.

Destoning

This process helps enhance the quality and purity of oil-bearing seeds by removing stones of the same size as oil-bearing seeds. The process is done using a density cum gravity separator with an aspiration system

De-Hulling

(For Cotton seeds and Groundnuts) A De-Huller is used to separate hulls from the seeds before sending the seeds for the next process.

Cooking

The oilseeds are sent to a vapour-tight cooker that conditions the seeds to the required temperature and rapture oil cells by flushing off moisture as steam. This process helps to lower the oil viscosity, thus easing separation during the oil extraction.

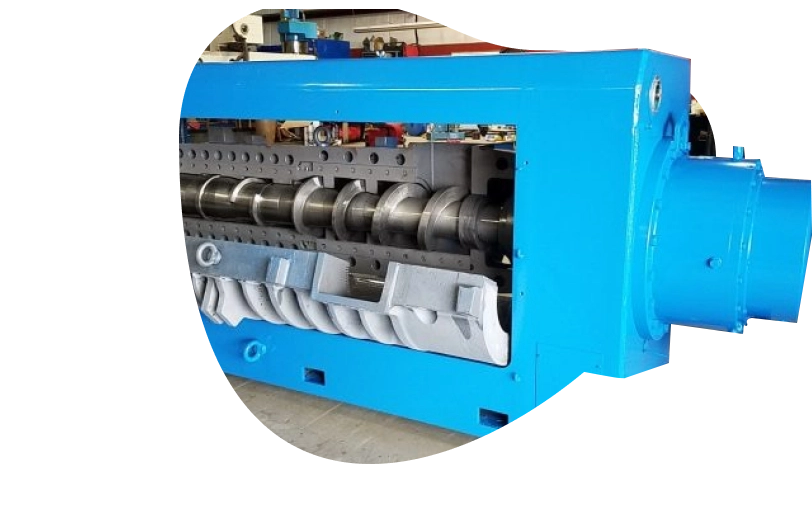

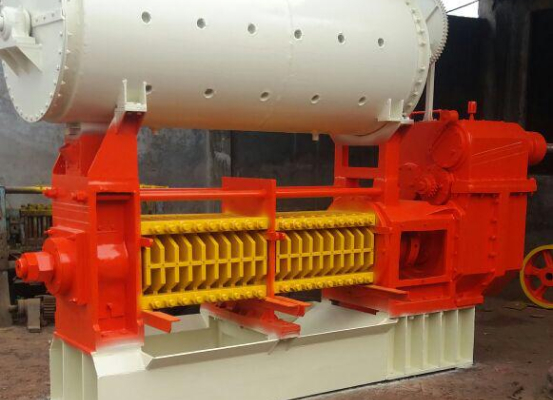

Crushing

It is the process of crushing oilseeds for getting the crushed oil & oil cake.

Oil Filtration

The last step of creating seed oil at N&T Engitech is oil filtration. This is the process of separating oil from solid particles, and it is essentially used for purifying oil.

Benefits of Our Seed Crushing Oil Plant

Our seed crushing oil plant offers numerous benefits to your operations. From high-quality oil production to increased efficiency, Let's discover the advantages

How We Work

N and T Engitech operates by providing innovative engineering solutions and services, leveraging expertise to address complex industrial challenges effectively.

Planning & Design

Initial phase involves project conception, site selection, & architectural & engineering design.

Construction & Execution

Once the planning and design phase is complete, actual construction begins.

Finishing & Commissioning

All systems & equipment are thoroughly tested & commissioned to ensure they operate as intended.

Spares

Spares as per your industrial requirements

Customize your industroial operations with our precision-engineered spare parts, tailored specifically to meet your unique needs.

Other Technology

Utilizing cutting-edge technologies, N&T provides engineering, procurement, and construction solutions for all equipment related to seed crushing procedures.

Why Choose Us

Choose N&T as your preferred oil seed crushing machine and plant manufacturer for unmatched quality, innovation, and reliable solutions that drive success.

Advanced Technology

Our machines incorporate cutting-edge technology, ensuring efficiency and precision in oil seed crushing. We stay at the forefront of technological advancements to provide you with the best solutions.

High-Quality Machines

We pride ourselves on delivering high-quality oil seed crushing machines that meet or exceed industry standards. Our machines are designed for precision & efficiency, ensuring top-notch oil production.

Environmentally Friendly Practices

We prioritize eco-friendly practices in our manufacturing processes and plant designs. Our solutions are designed to minimize environmental impact, ensuring sustainability in your operations.

Global Reach

We serve clients worldwide, making our oil seed crushing machines and plant solutions accessible to a global market. Regardless of your location, we're here to meet your needs.

Our Respected Clients

We are honored to collaborate with the most top organizations in the Engineering Procurement and Construction industry.

Projects

Our Accomplished Projects

N&T steadily offers cutting-edge expertise to big and small enterprises for a diverse range of uses and environments all over the world. Browse through our completed project list.

Our Certification & Awards

N&T employs the most cutting-edge, creative professionals who are actively learning about evolving EPC standards.

Experience

Clients

Best Team

Our Blog

Browse most recent blog & news from N&T. View Engineering Procurement Construction related news, and articles.

Frequently Asked Questions

Our seed crushing plants are available in a range of capacities, spanning from a modest 10 TPD to a maximum of 1000 TPD. If you're just starting out and unsure about the suitable size for your needs, we encourage you to Contact us. Our team will assist you in determining the most appropriate seed crushing plant size for your specific requirements.

N&T Engitech designs and develops factories equipped with various levels of automation to suit different operational needs, including manual, semi-automatic, and fully automatic systems. As a renowned edible oil plant manufacturer, we focus on automating critical processes to minimize the need for manpower. This includes automation in the feeding process, the crushing operation, and the handling of the output.

The cost range for our seed crushing machines in the crushing plants starts at $10,000 and varies depending on the specific requirements and capacities desired. Each machine is tailored to meet different operational needs, which influences the final cost.

Yes, our seed processing plants are fully compliant with all relevant food safety regulations and quality standards, ensuring that our operations meet the highest levels of safety and quality in the industry.

Yes, we provide comprehensive training for operating and maintaining the oil seed crushing machine in the plant. Our focus is on training local personnel as much as possible. This approach is beneficial as it reduces the need to bring in external operators, promoting local expertise and fostering self-sufficiency in managing and maintaining the seed crushing plant.